Products

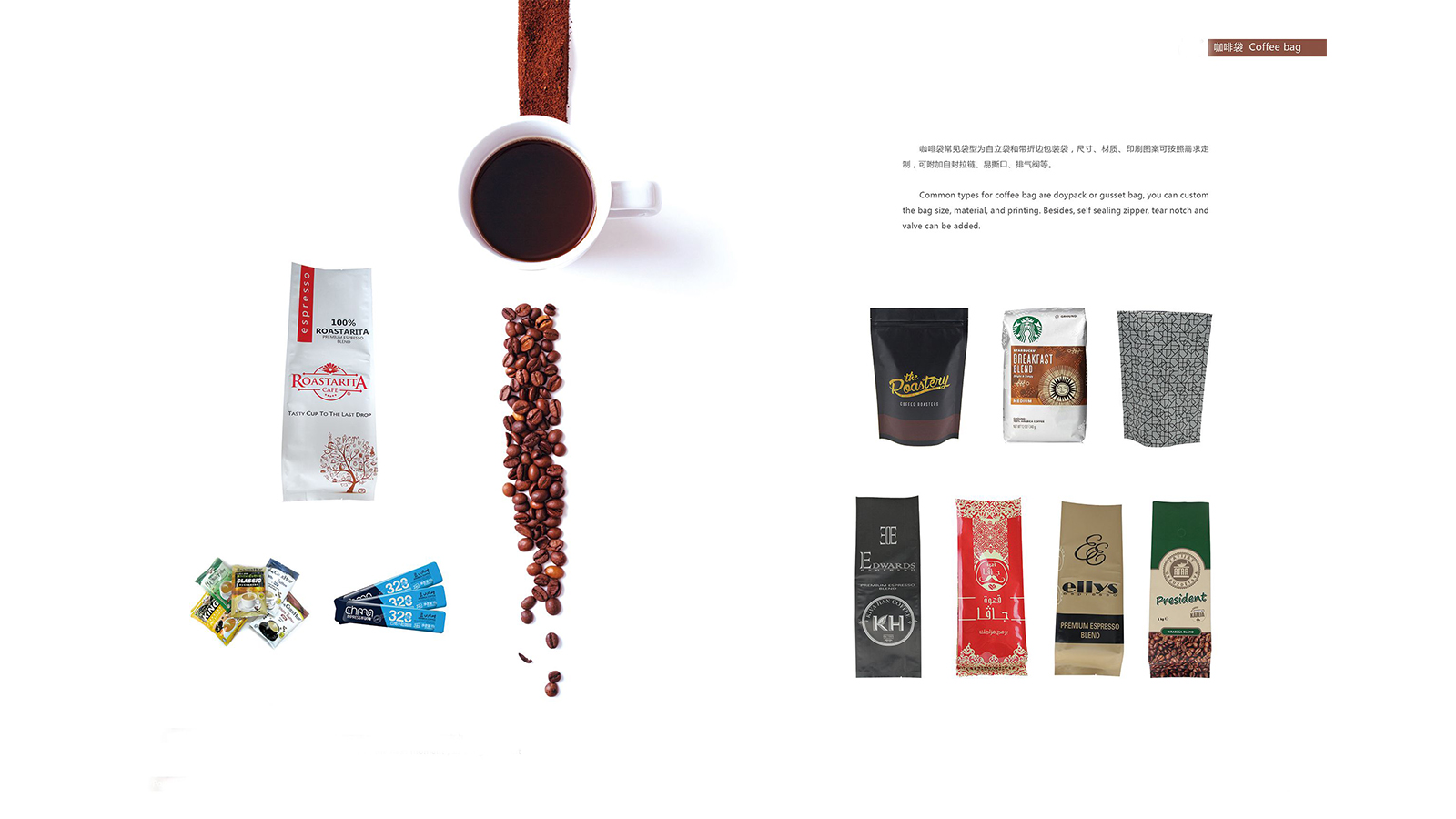

Custom Printed Mylar Stand Up Bag Food Grade Seasoning Bags

Custom Printed Mylar Stand Up Bag

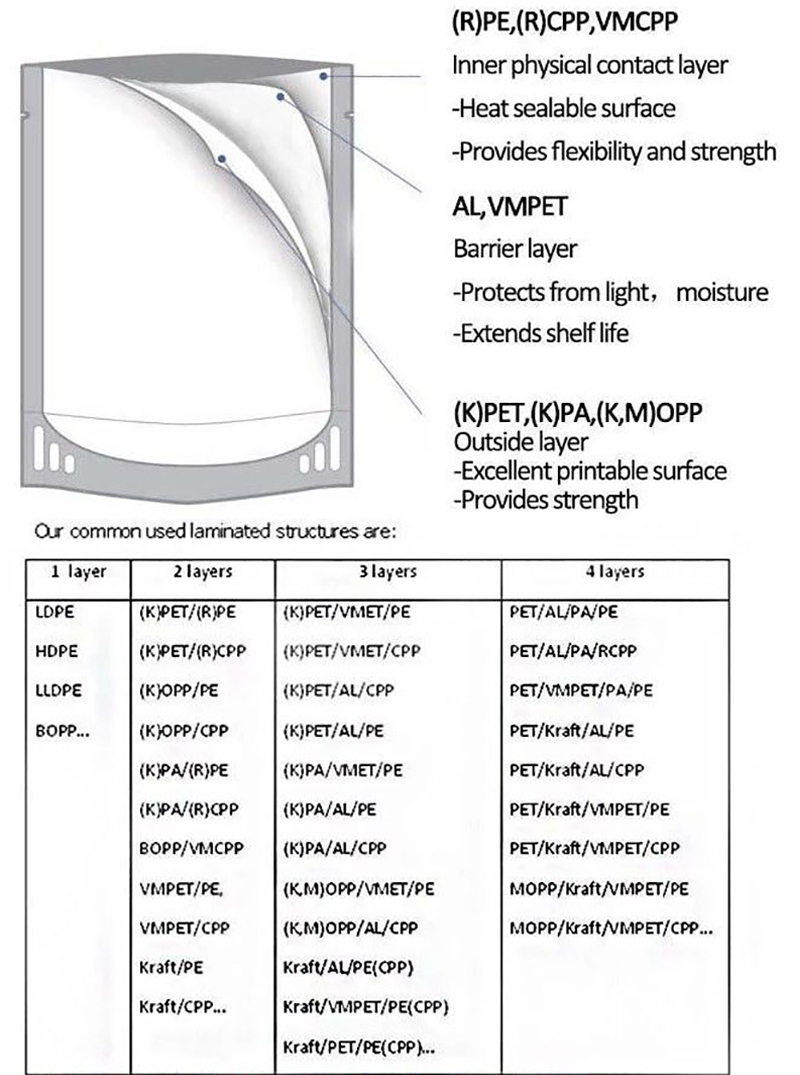

1. Material Composition

Seasoning plastic bags are typically made from food-grade polyethylene or polypropylene, ensuring they are safe for direct contact with food. These materials are chosen for their durability, flexibility, and resistance to punctures, which are essential qualities for handling various seasonings and liquids.

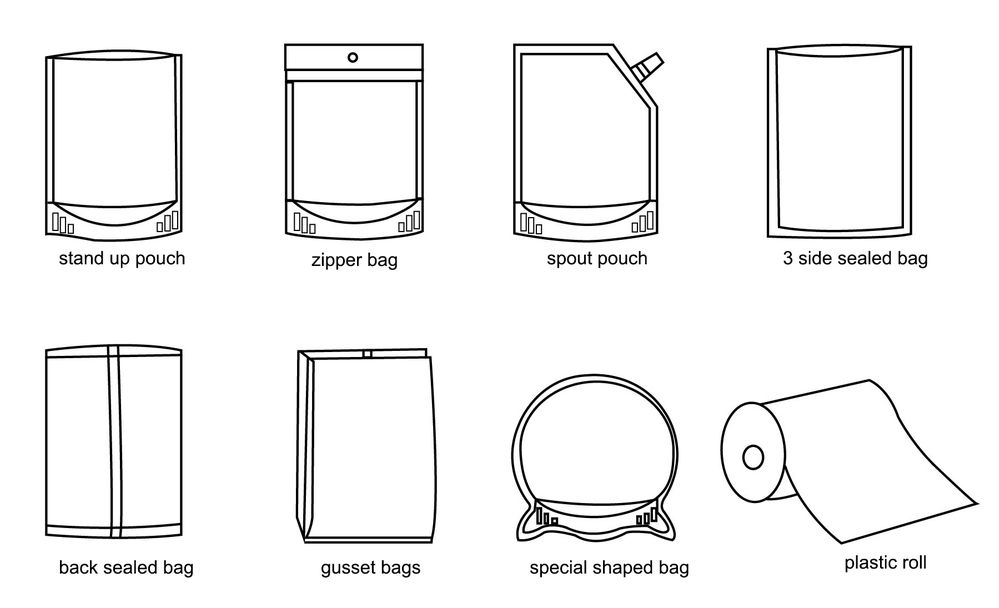

2. Design and Structure

The design of seasoning plastic bags is both practical and user-friendly. They usually feature a resealable zip-lock closure or a twist-tie mechanism to ensure the contents remain secure. The bags are transparent, allowing for easy identification of the contents without the need to open them. They come in a range of sizes, from small bags suitable for individual spices to larger ones for bulk storage.

3. Ease of Use

Seasoning plastic bags are designed for convenience. The zip-lock or resealable closure makes them easy to open and close, which is particularly useful for repeated access. Their flexible nature allows them to conform to the shape of their contents, making them space-efficient in storage. They can be labeled with markers or stickers, providing an easy way to organize and identify different seasonings.

4. Airtight and Moisture-Resistant

One of the key characteristics of seasoning plastic bags is their ability to provide an airtight and moisture-resistant environment. This helps to preserve the freshness and potency of the seasonings by protecting them from air, moisture, and contaminants. The secure seal prevents leaks and spills, ensuring the seasonings remain intact and uncontaminated.

5. Consumer Benefits

The primary benefits of seasoning plastic bags lie in their convenience and effectiveness in preserving the quality of seasonings. They provide an easy way to store, organize, and access a variety of seasonings, ensuring that flavors remain fresh and potent. Their lightweight and flexible design make them ideal for both home use and travel, while the resealable closure ensures contents are securely stored without the risk of spills.

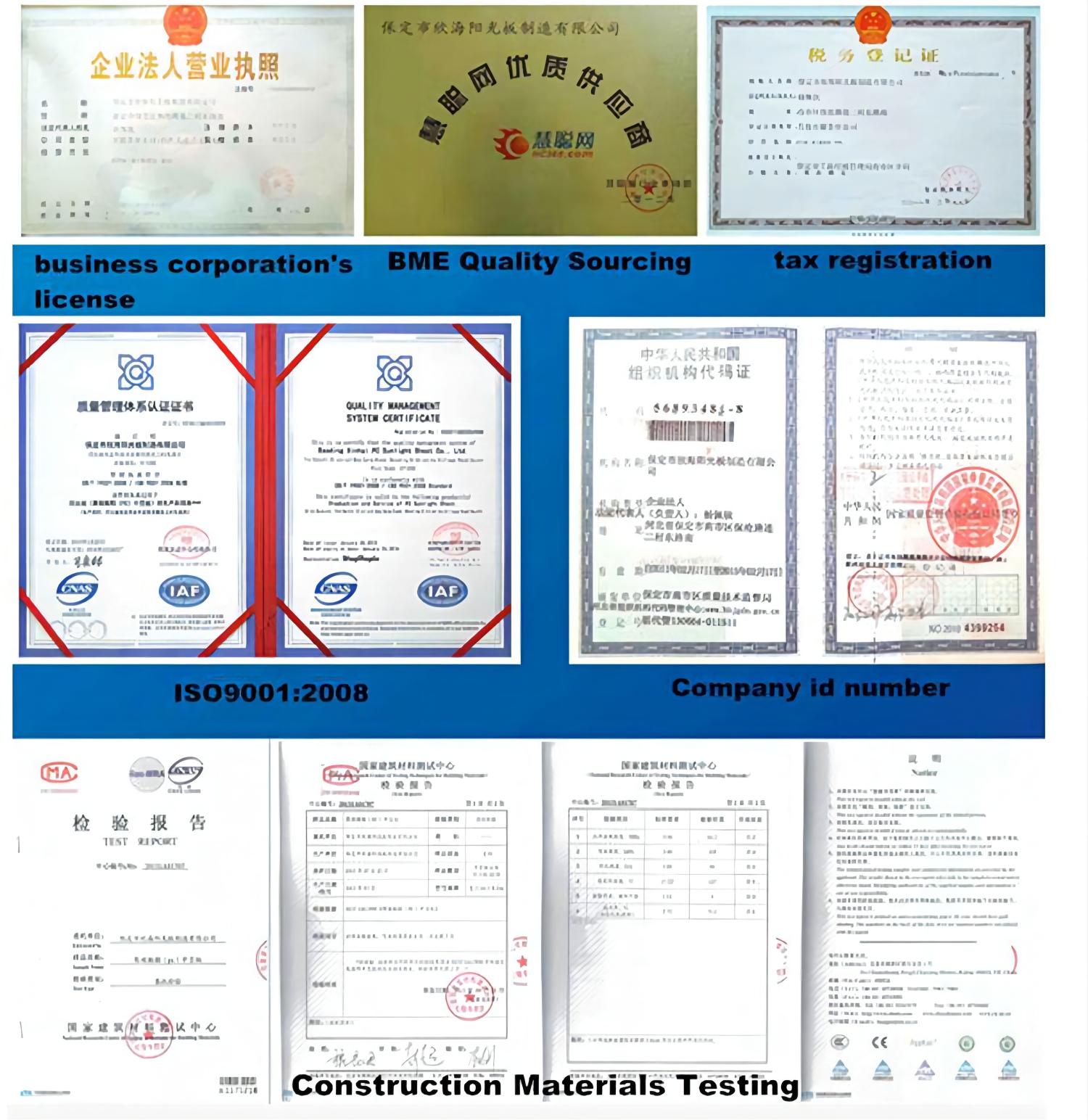

We are a factory, which locates Liaoning Province of China, welcome to visit our Factory.

For ready made products, the MOQ is 1000 pcs, and for customized goods, it depends on the size and printing of your design. Most of the raw material is 6000m, MOQ=6000/L or W per bag, usually about 30,000 pcs. The more you order, the lower the price will be.

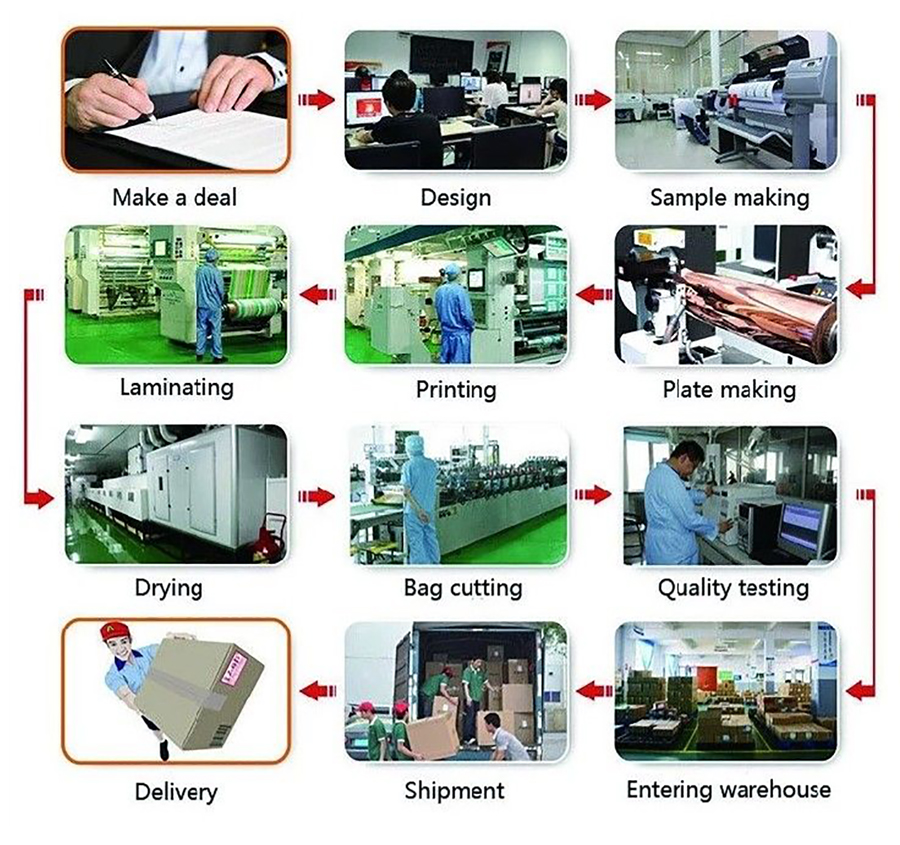

Yes, that's the main work we do. You can give us your design directly, or you can provide the basic information to us, we can make free design for you. Besides, we also have some ready made products, welcome to inquire.

That will depend on your design and quantity, but usually we can finish your order within 25 days after we get the deposit.

First pls tell me the usage of the bag so that i can suggest you the most suitable material and type, eg, for nuts, the best material is BOPP/VMPET/CPP, you can also use craft paper bag, most type is stand up bag, with window or without window as you require. If you can tell me the material and type you want, that will be best.

Second, the size and thickness is very important, this will influence the moq and cost.

Third, the printing and color. You can have at most 9 colors on one bag, just the more color you have, the higher the cost will be. If you have the exact printing method, that will be great; if not, pls provide the basic information you want to print and tell us the style you want, we will do free design for you.

No. Cylinder charge is a one time cost, next time if you reorder same bag same design, no more cylinder charge need. Cylinder is based on your bag size and design colors. And we will keep your cylinders for 2 years before you reorder.