Products

250g Custom Printed Chocolate Powder, Cake Powder, Powder Packaging

250g Custom Printed Chocolate Powder Packaging

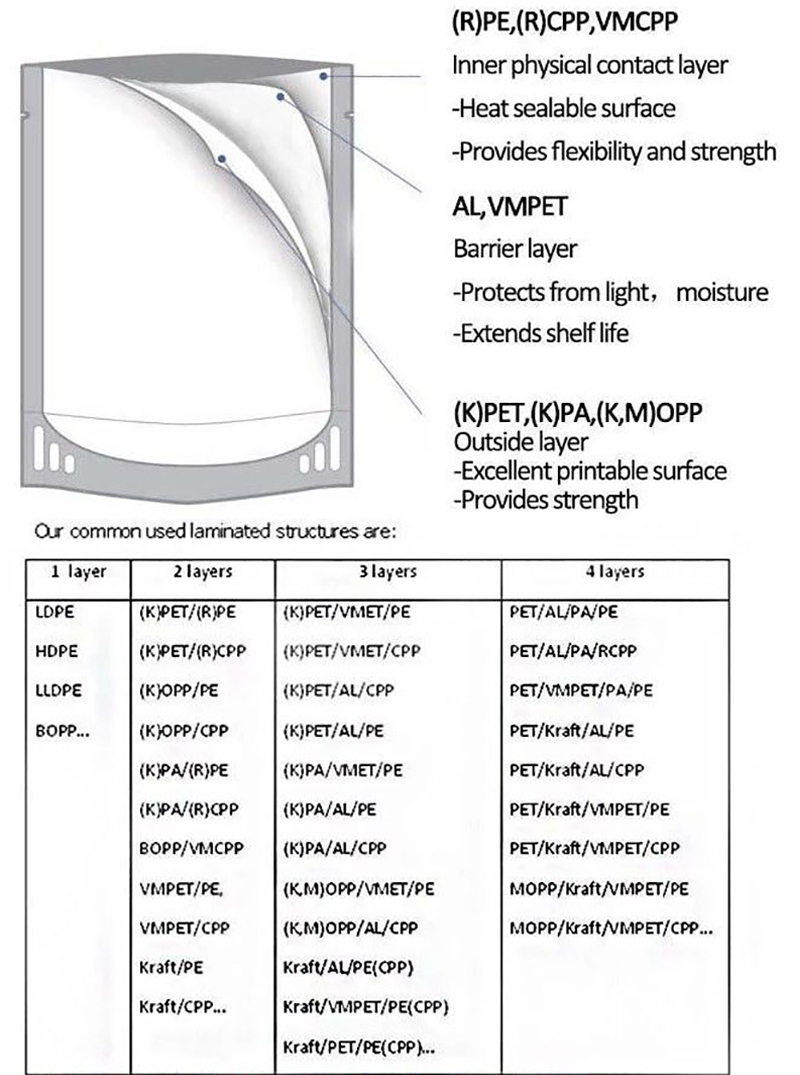

1.Material Selection:

Food-Grade Materials: Ensure that the packaging material is food-grade and compliant with relevant food safety regulations. Common materials include laminated films, polyethylene (PE), polypropylene (PP), and metallized films.

Moisture and Oxygen Barriers: Choose materials with moisture and oxygen barrier properties to protect the powdered products from moisture absorption and oxidation, which can affect quality and shelf life.

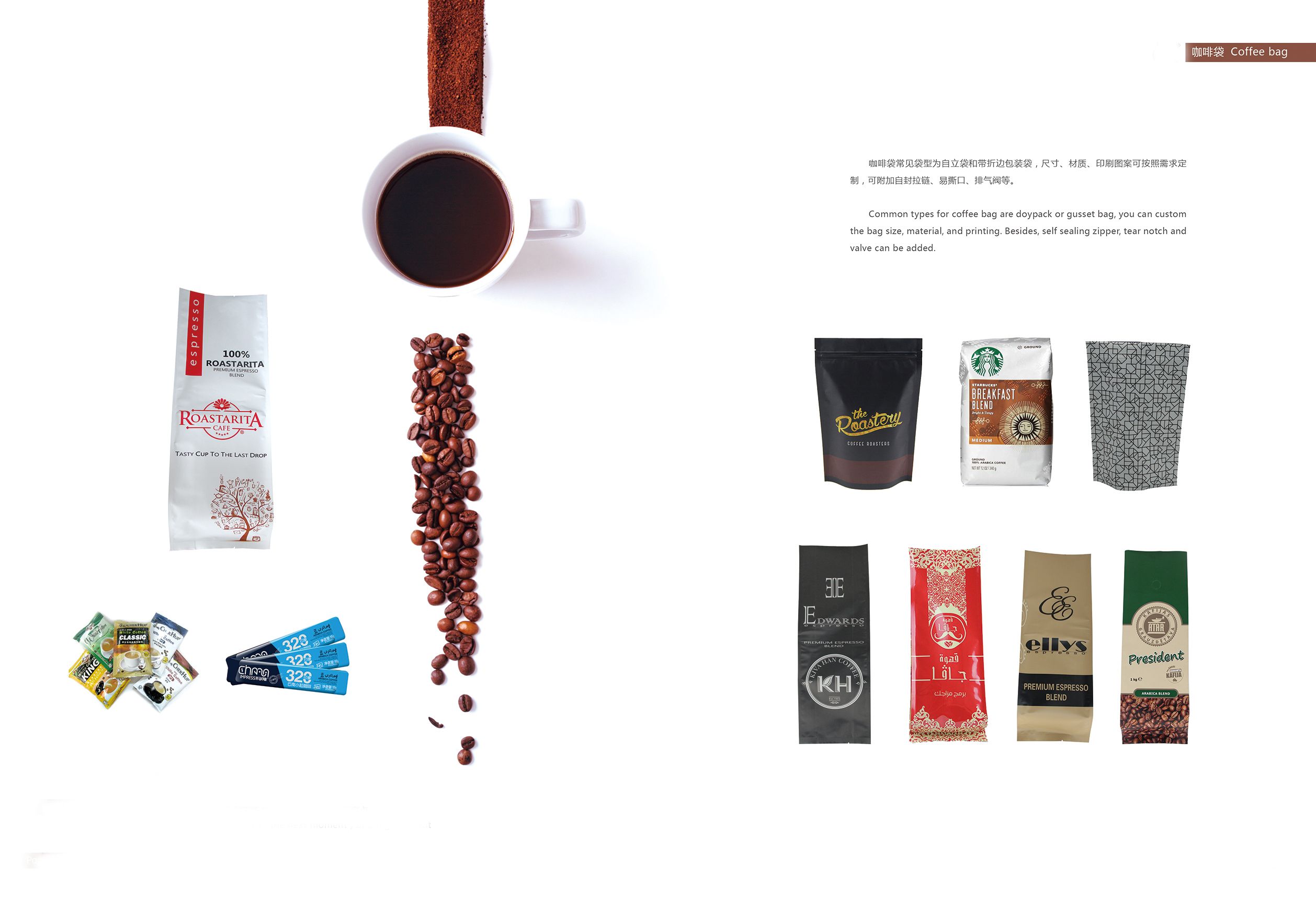

2. Bag Style:

Flat Pouches: These are simple, flat bags suitable for various powder products.

Stand-Up Pouches: Stand-up pouches are self-supporting and provide excellent visibility on store shelves.

Gusseted Bags: Gusseted bags have expandable sides that allow for more significant volume capacity.

Quad-Seal Bags: Quad-seal bags have reinforced corners that provide added strength and support.

3. Size and Capacity:

Determine the appropriate bag size and capacity to accommodate the volume of chocolate powder, cake powder, or other powdered products.

4. Closure Mechanism:

Common closure options include heat-sealing, zip-lock closures, resealable zippers, and adhesive strips. Resealable closures are convenient for consumers to reseal the bag after use.

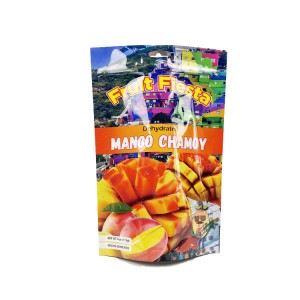

5. Printing and Branding:

Custom printing allows you to add branding elements, product information, labels, barcodes, and promotional graphics to the packaging for marketing purposes.

6. Window Features:

Clear windows or transparent panels in the bag design can showcase the product, allowing consumers to see the quality and texture of the powder inside.

7. Tear Notches:

Tear notches or easy-open features facilitate effortless opening of the packaging without the need for scissors or other tools.

8. Regulatory Compliance:

Ensure that the packaging complies with relevant food safety regulations, including allergen labeling, nutritional facts, ingredient lists, and any other required information.

9. Sustainability:

Consider eco-friendly packaging options, such as recyclable materials or biodegradable films, to align with sustainability goals and consumer preferences.

10. Quantity and Ordering:

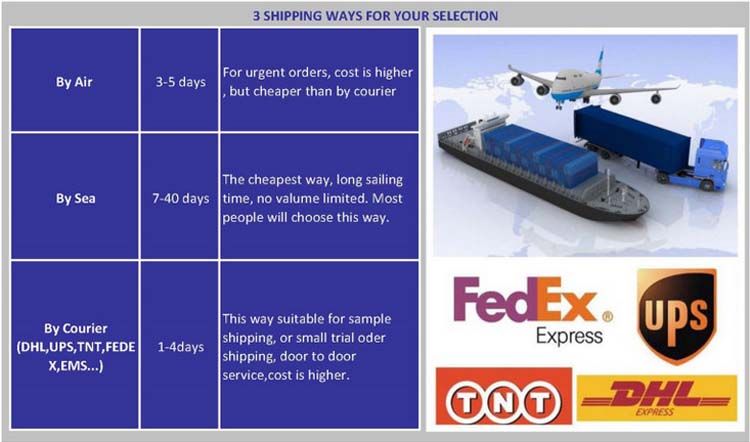

Determine the quantity of bags needed and consider minimum order requirements when selecting a supplier or manufacturer.

11. Quality Control:

Ensure that the packaging supplier has robust quality control processes in place to maintain consistency and product integrity.

12. Sampling and Prototyping:

Some manufacturers offer sampling and prototyping services, allowing you to test the packaging before full-scale production.

We also have the following range of bags for your reference.

A: Our factory MOQ is a roll of cloth, it’s 6000m long, about 6561 yard. So it depend on your bag size, you can let our sales figure it for you.

A: The production time is about 18-22 days.

A: Yes, but we don’t suggest make a sample, the model cost is too expensive.

A: Our designer can make your design on our model, we will confirm with you can produce it according to the design.