Products

High Strength Package Vacuum Cleaner Bags New Design Food Vacuum Plastic Bag Storage Freezer Dried Fish

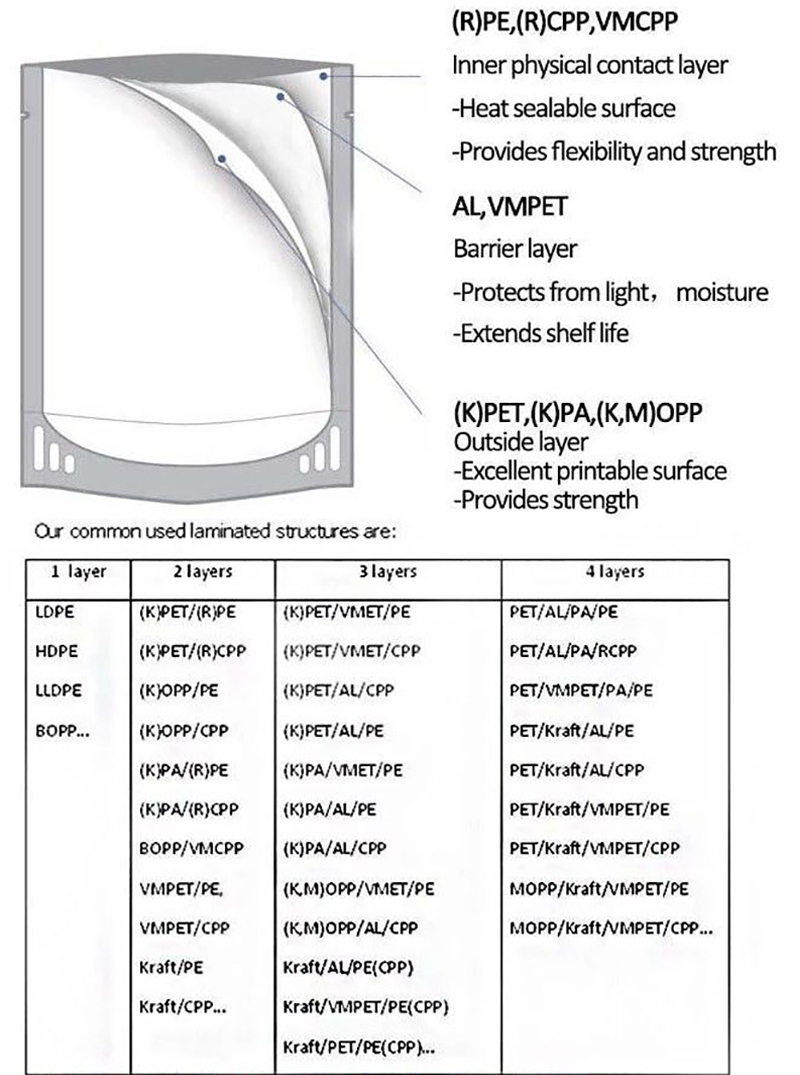

1. Material: Vacuum cleaner bags are typically made from a variety of materials, including paper, synthetic fabrics, and microfiber. The choice of material affects the bag's filtration efficiency and durability.

2. Filtration: Vacuum cleaner bags are designed to filter out fine particles, including dust mites, pollen, pet dander, and small debris, to prevent them from being released back into the air as you vacuum. High-quality bags often feature multiple layers to improve filtration.

3. Bag Type: There are various types of vacuum cleaner bags, including:

Disposable Bags: These are the most common type of vacuum cleaner bags. Once they are full, you simply remove and replace them with a new bag. They come in different sizes to fit various vacuum models.

Reusable Bags: Some vacuum cleaners use washable and reusable cloth bags. These bags are emptied and cleaned after use, reducing the ongoing cost of disposable bags.

HEPA Bags: High-Efficiency Particulate Air (HEPA) bags have advanced filtration capabilities and are particularly effective at trapping small allergens and fine dust particles. They are often used in vacuums designed for allergy sufferers.

4. Bag Capacity: Vacuum cleaner bags come in different sizes and capacities to accommodate varying amounts of debris. Smaller bags are suitable for handheld or compact vacuums, while larger bags are used in full-sized vacuum cleaners.

5. Sealing Mechanism: Vacuum cleaner bags feature a sealing mechanism, such as a self-sealing tab or a twist-and-seal closure, to prevent dust from escaping when you remove and dispose of the bag.

6. Compatibility: It's crucial to ensure that you use vacuum cleaner bags that are compatible with your specific vacuum model. Different vacuum brands and models may require different bag sizes and styles.

7. Indicator or Full Bag Alert: Some vacuum cleaners come with a full bag indicator or alert system that signals when the bag needs to be replaced. This feature helps prevent overfilling and loss of suction power.

8. Allergen Protection: For individuals with allergies or asthma, vacuum cleaner bags with HEPA filtration or allergen-reducing features can be particularly beneficial in trapping allergens and improving indoor air quality.

9. Odor Control: Some vacuum cleaner bags come with odor-reducing properties or scented options to help freshen the air as you clean.

10. Brand and Model Specific: While many vacuum cleaner bags are universal and fit various models, some vacuum manufacturers offer bags specifically designed for their machines. These bags may be recommended for optimal performance.

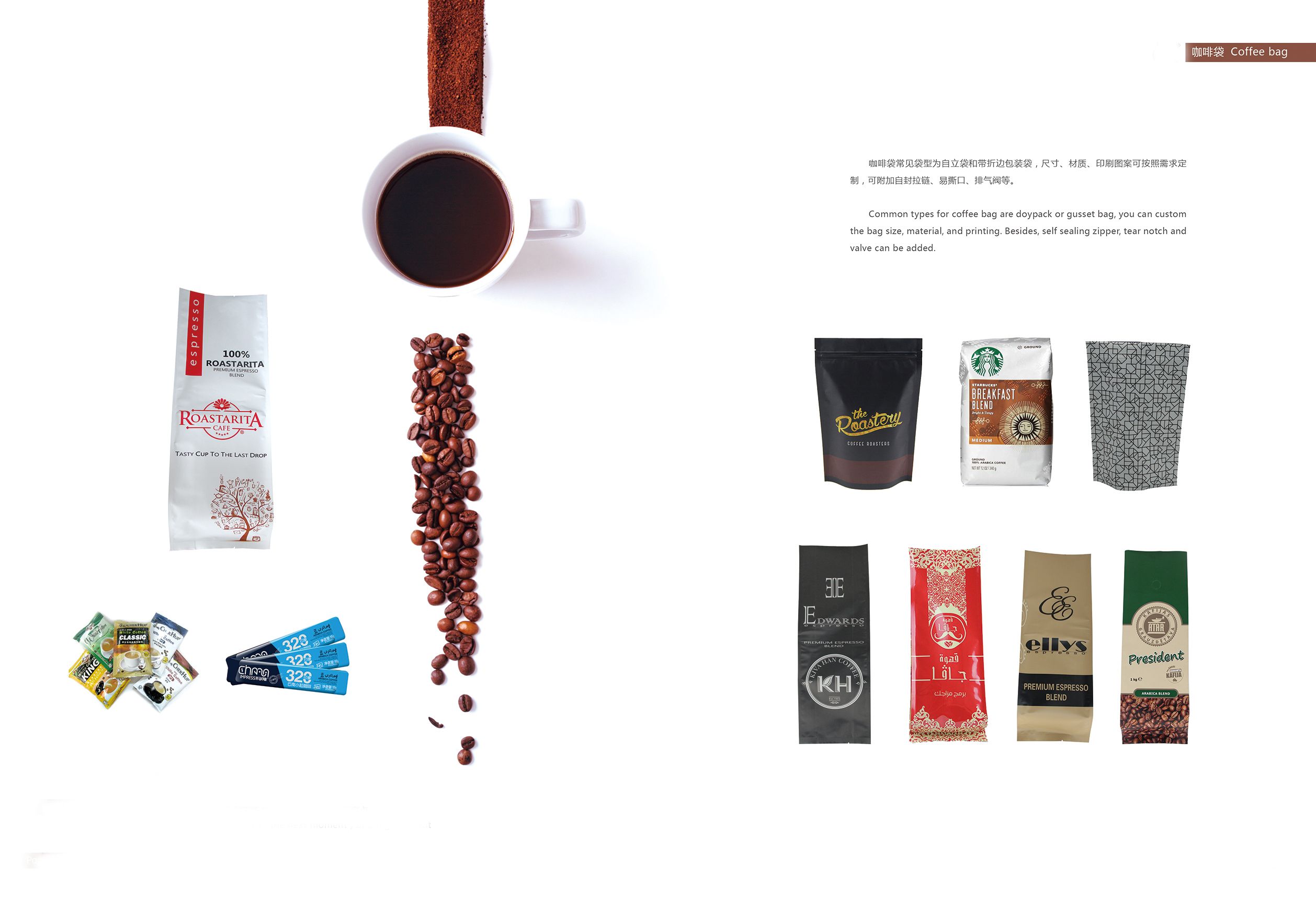

We also have the following range of bags for your reference.

A: Our factory MOQ is a roll of cloth, it’s 6000m long, about 6561 yard. So it depend on your bag size, you can let our sales figure it for you.

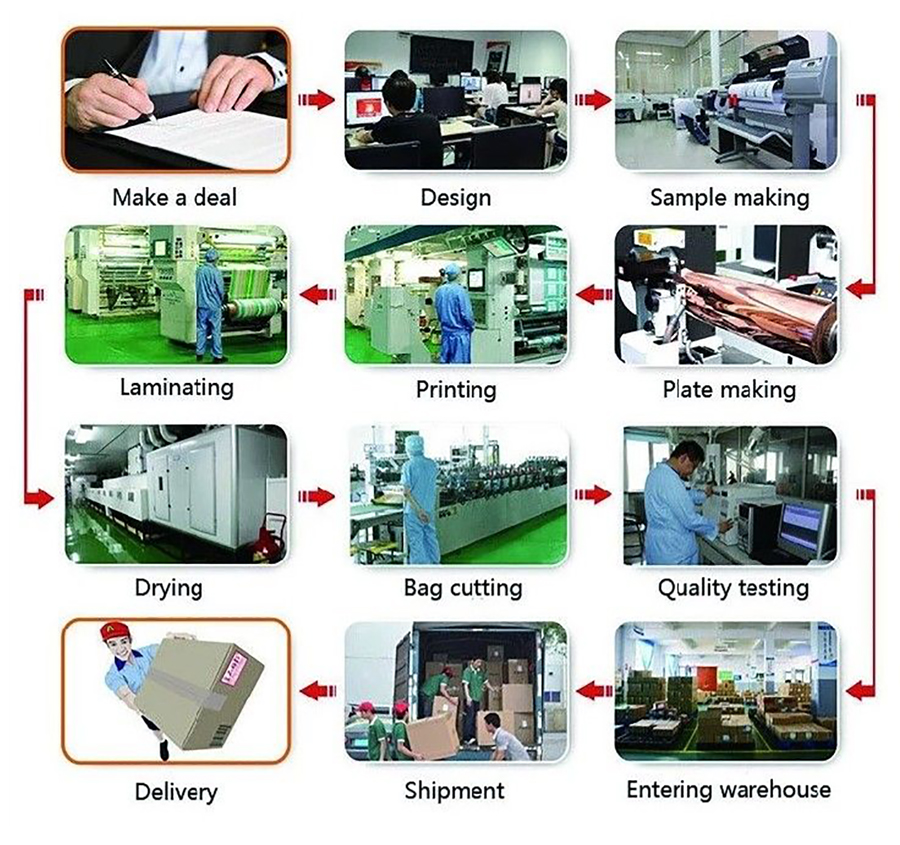

A: The production time is about 18-22 days.

A: Yes, but we don’t suggest make a sample, the model cost is too expensive.

A: Our designer can make your design on our model, we will confirm with you can produce it according to the design.